Ground Solution|Radiation Solution: Temporary Road Mats| Borated Polyethylene Sheets

-

Ground SolutionsOEM DESIGN

-

Radiation ProtectionCNC PROCESSING

-

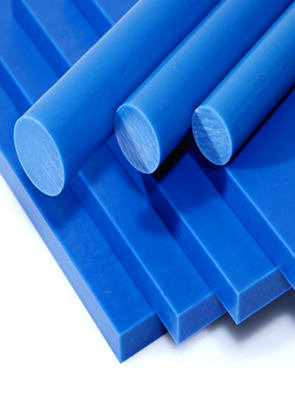

UHMWPE ProductOnesite Solution

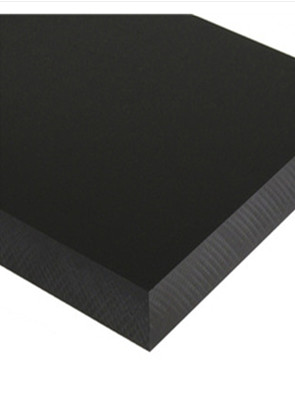

Borated Polyethylene Sheets

作者:admin 发布时间:2021-02-05 17:54 浏览:

Borated polyethylene is one of the most commonly used anti - neutron materials in neutron shielding. Because of its high strength, uniform density, acid and alkali corrosion resistance and superior neutron shielding performance, this material has been widely used in neutron shielding protection. At present, China's boron-containing polyethylene is mainly imported, and most is 5% boron-containing polyethylene. In order to improve the shielding effect of borated polyethylene and solve the problem that boron-containing polyethylene is difficult to be commercialized in China, a borated polyethylene board with boron content of 8% was developed and its sub-shielding performance was studied. The results show that when the thickness of the boron-containing polyethylene plate is 10cm, the shielding efficiency of 241Am-Be neutron is 82.5%, and the shielding efficiency of 252Cf neutron is 90.9%. When the thickness of the boron-containing polyethylene plate is 20cm, the shielding efficiency for neutrons from 241Am-Be source is 95.6%, and the shielding efficiency for neutrons from 252Cf source is 97.8%. When the thickness of the borated polyethylene plate is 30cm, the shielding efficiency of 241Am-Be neutron is 98.2%, and the shielding efficiency of 252Cf neutron is 99.3%. It can be concluded that the 8% boron-containing polyethylene plate is an efficient neutron shielding material, which can be effectively used for neutron shielding protection in neutron and neutron and γ mixed radiation fields.

The technical problems to be solved in the application of ionizing radiation protection in nuclear technology :(1) How to design 8% boron-containing polyethylene board; (2) How to make boric acid and polyethylene melt at the same temperature in the process, and not form metaboric acid and pyroboric acid, so that it is easy to mix, heat, extrusion and roll forming. 1. According to the chemical formula H3BO3 and atomic weight of boric acid, the percentage of boron is calculated to be 17.48%, and then the weight percentage of boric acid should be added in 100 kg boron-containing polyethylene is calculated to be 46%, and 8% boron-containing polyethylene board is designed. 2, the development of boric acid processing temperature can be temporarily raised to 120℃ without decomposition of A solvable agent, but also can reduce the melting point of high density polyethylene to 120℃ B solvable agent, to solve the problem of boric acid coking. Applications: neutron radiation protection in nuclear power stations, medium (high) energy accelerators, atomic reactors, nuclear submarines, medical accelerators, neutron therapy equipment and other places.

Our company specializes in producing borated polyethylene sheet, lead boron polyethylene sheet and other products. We can do CNC processing according to the drawings. The boron content varies form 2% to 50%. Welcome to contact us !

The technical problems to be solved in the application of ionizing radiation protection in nuclear technology :(1) How to design 8% boron-containing polyethylene board; (2) How to make boric acid and polyethylene melt at the same temperature in the process, and not form metaboric acid and pyroboric acid, so that it is easy to mix, heat, extrusion and roll forming. 1. According to the chemical formula H3BO3 and atomic weight of boric acid, the percentage of boron is calculated to be 17.48%, and then the weight percentage of boric acid should be added in 100 kg boron-containing polyethylene is calculated to be 46%, and 8% boron-containing polyethylene board is designed. 2, the development of boric acid processing temperature can be temporarily raised to 120℃ without decomposition of A solvable agent, but also can reduce the melting point of high density polyethylene to 120℃ B solvable agent, to solve the problem of boric acid coking. Applications: neutron radiation protection in nuclear power stations, medium (high) energy accelerators, atomic reactors, nuclear submarines, medical accelerators, neutron therapy equipment and other places.

Our company specializes in producing borated polyethylene sheet, lead boron polyethylene sheet and other products. We can do CNC processing according to the drawings. The boron content varies form 2% to 50%. Welcome to contact us !